DAM-Q

Simplify Production and Quality Approvals

Level Up Production with Existing Data

Leverage your GxP Asset Management data to streamline production from preparation to quality approvals.

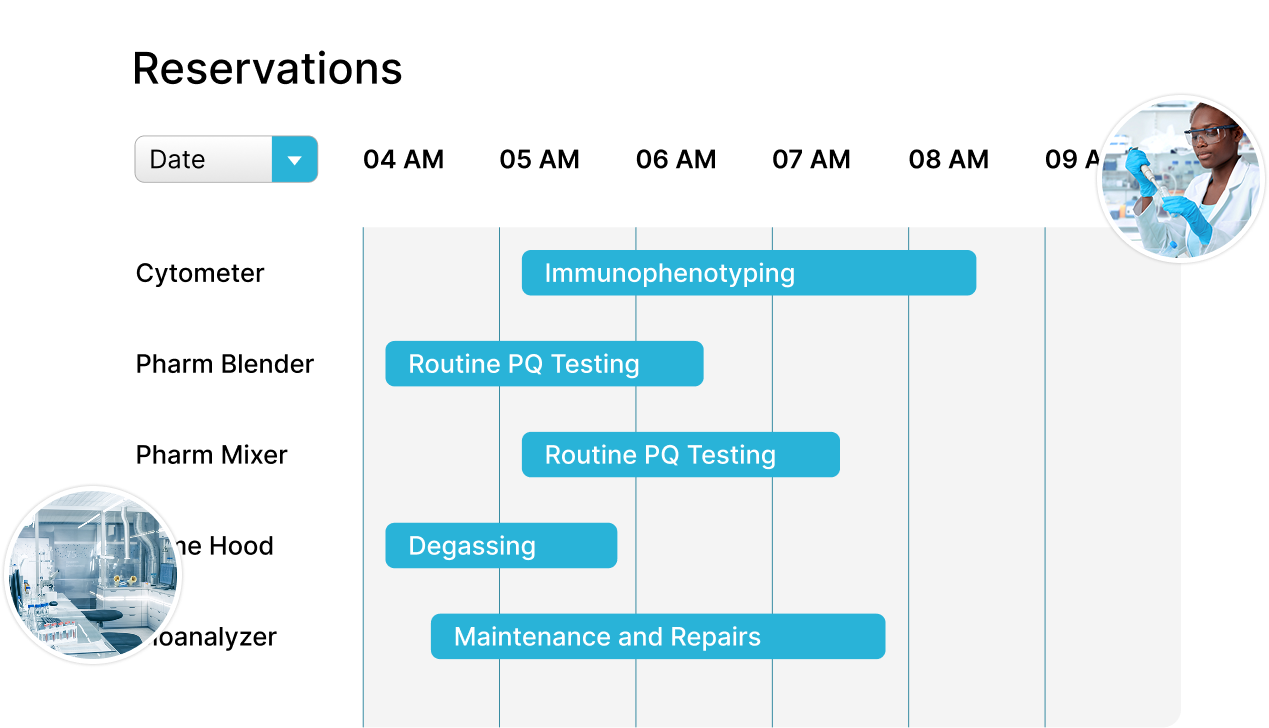

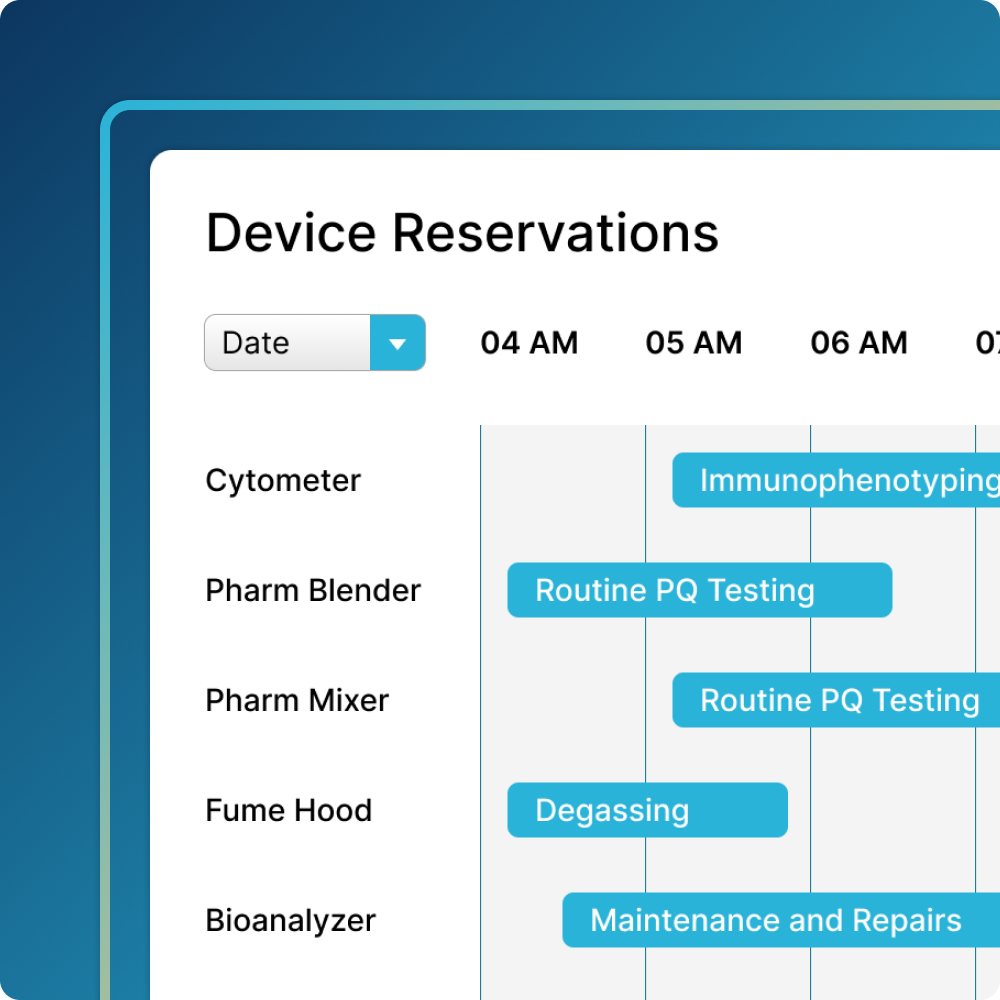

Stay on Schedule

Reserve the equipment you need—or easily find appropriate alternatives—for every production run.

Reduce Time in Quarantine

Generate Quality-ready reports to streamline batch approvals.

Remediate Issues Quickly

Access a centralized audit history of all assets to address any deviations.

The Next Stage of Digital Transformation

Accelerate time-to-market timelines by aligning manufacturing and quality teams and processes.

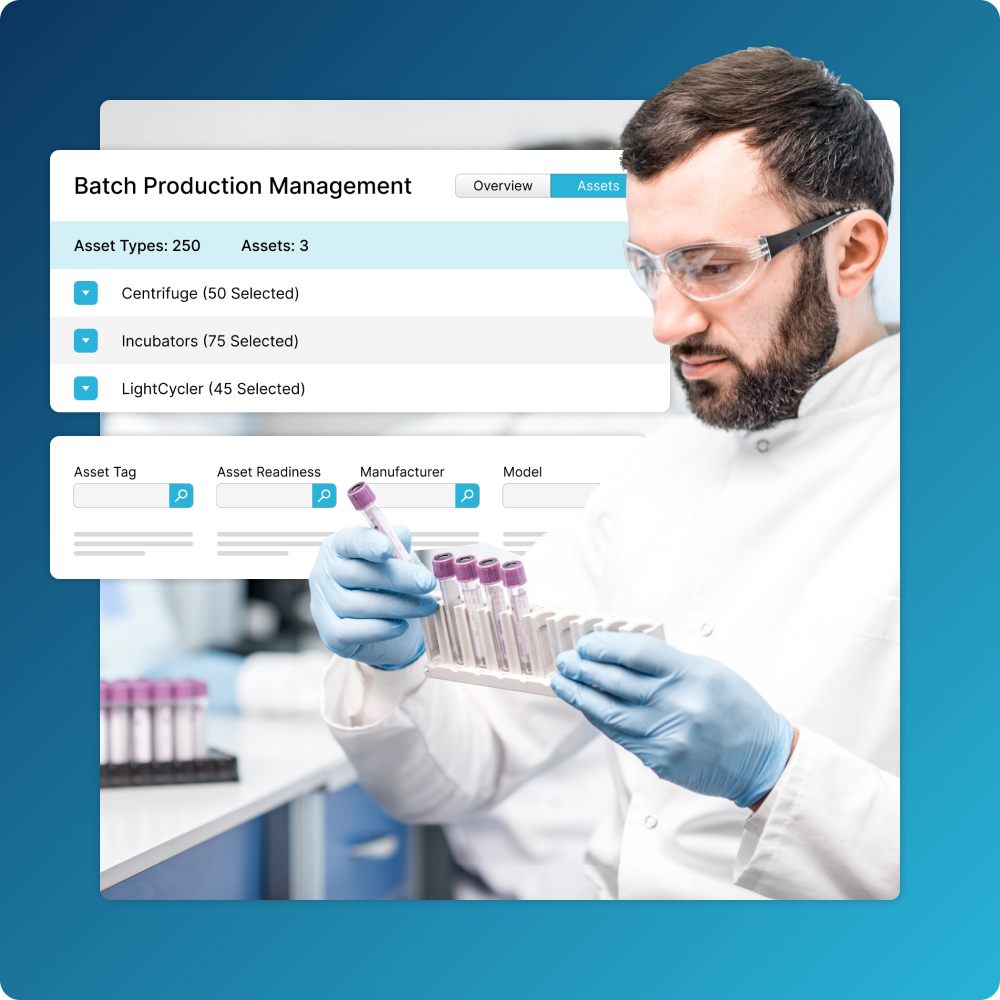

Simplify Production and Planning

Secure the assets you need for every batch, every time.

- Bulk reserve multiple assets for each batch

- Receive notifications if an asset is unavailable with recommendations for alternative equipment

- Leverage “previously used” templates with required equipment for similar batches

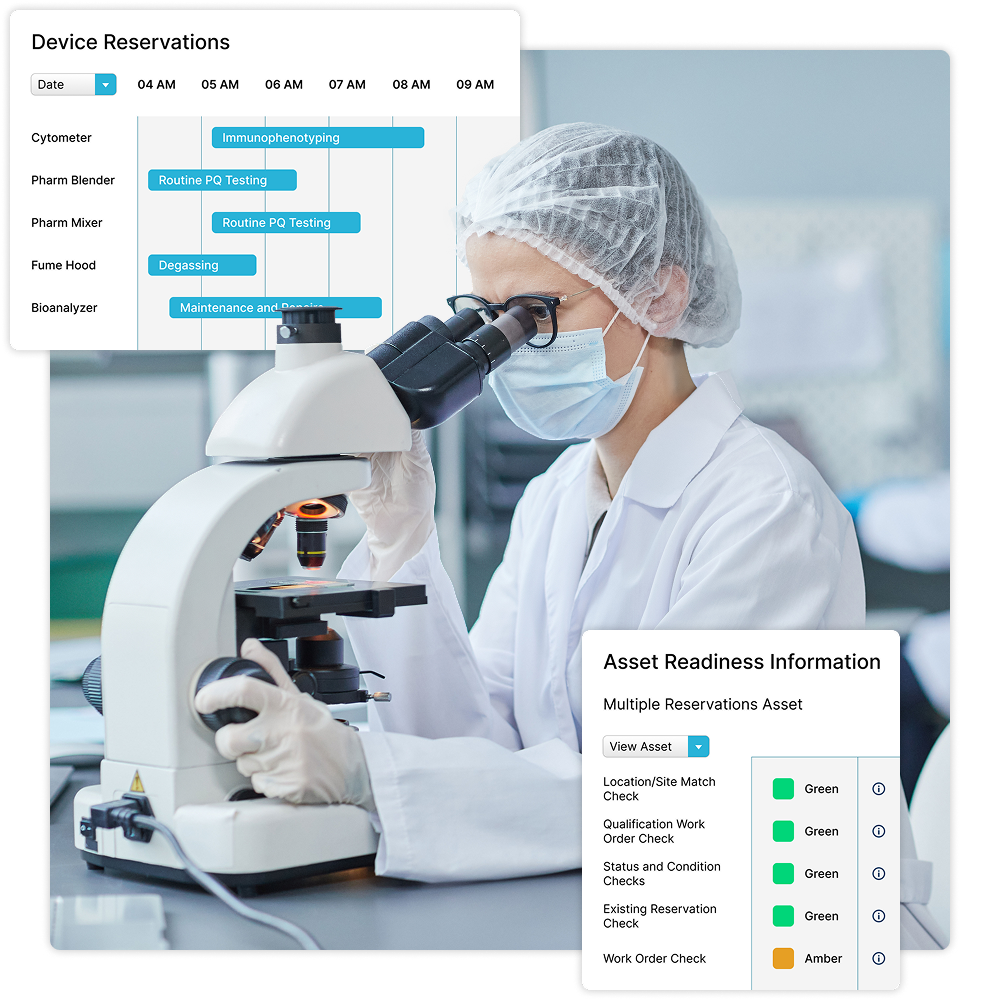

Manage Asset Readiness

Prevent surprises with insights into asset health and availability.

- Define rule sets based on risk factors to determine asset readiness

- Understand which assets are available for use based on red, amber, green status

- Identify alternative equipment to keep production on track

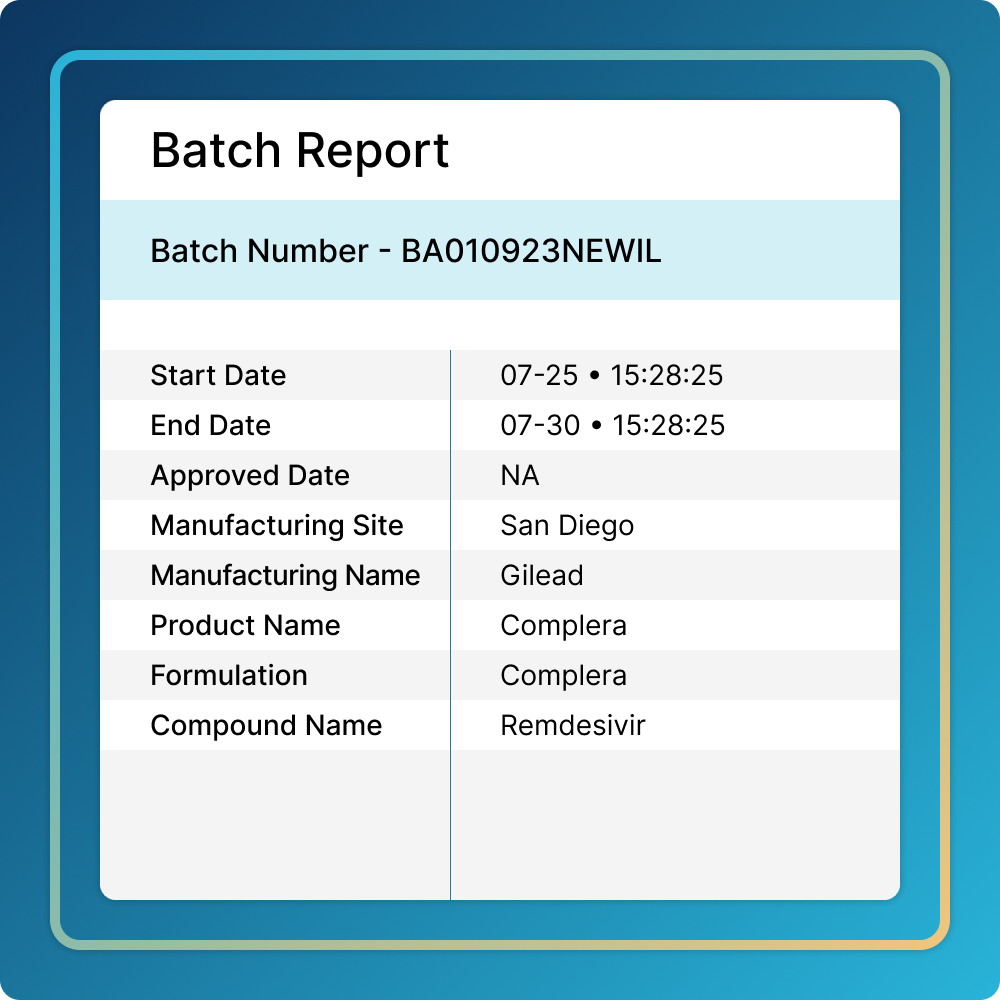

Streamline Quality Batch Review

Access validated documentation about the manufacturing process.

- Generate reports with assets used in each batch, including asset images

- Support compliance with immutable e-signed batch reports and audit trails

- Configure approval workflows to facilitate overall batch approval or rejection

Optimize Asset Costs

Identify cost savings through utilization data, and accelerate revenue through improved time to market.

- Enable asset performance management specific to each manufactured product

- Optimize asset inventory to reduce under-utilized assets

- Speed time to market by optimizing the batch review timeline

See It In Action

Contact us for a demo to see how you can modernize your production processes.

REQUEST A DEMO