Asset data is the information that tells maintenance teams what they’re responsible for, how equipment is performing, and what needs to happen next. It’s the difference between managing maintenance with confidence and managing it by memory.

When asset data is clear and consistent, maintenance work is easier to plan, easier to execute, and easier to explain. When it isn’t, work gets done based on what people remember instead of what’s documented in the system, and that’s where problems start.

What Is Asset Data?

Asset data is the collection of details that describe an asset throughout its lifecycle. It connects physical equipment in the field to the maintenance processes used to support it.

At its core, asset data answers a few basic questions:

- What is this asset?

- Where is it located?

- What condition is it in?

- What work has been done on it?

If those questions can’t be answered quickly and consistently, maintenance becomes reactive and harder to control.

What Information Counts as Asset Data?

Asset data is often misunderstood as just an equipment list. In reality, it includes several connected types of information.

1. Asset Identification

This defines what the asset is:

- Asset name or tag

- Equipment type

- Manufacturer, model, and serial number

- Install date and expected life

Without clear identification, maintenance history becomes fragmented or unusable.

2. Location and Asset Structure

This shows where the asset lives and how it fits into a system:

- Site, building, floor, and room

- Parent-child relationships between systems and components

Good structure helps teams understand impact. A failed component matters more when you know what system it supports.

3. Maintenance History

This captures how the asset has been maintained:

- Preventive maintenance tasks

- Corrective and emergency work

- Labor hours and parts used

- Downtime and failure notes

This history is what allows teams to spot patterns instead of repeating the same fixes.

4. Condition and Performance Information

This reflects how the asset is actually performing:

- Inspection results

- Condition ratings

- Usage or runtime data

Condition data helps teams move away from “we’ve always done it this way” maintenance.

5. Cost and Risk Details

This connects maintenance to business decisions:

- Maintenance spend over time

- Asset criticality

- Risk of failure

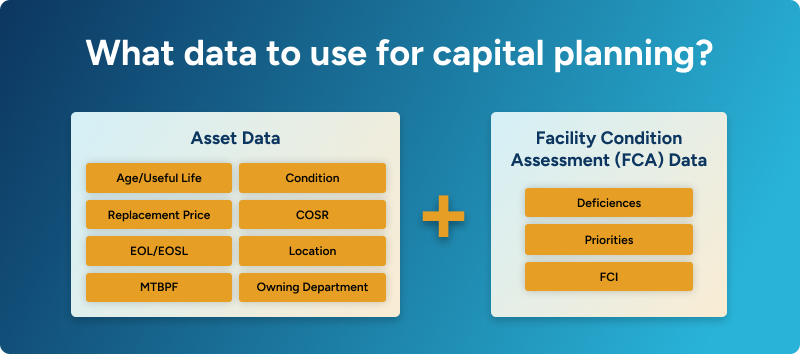

This data is essential when maintenance leaders need to explain priorities or justify budgets. Learn more about the critical data needed for facilities capital planning here.

Why Asset Data Matters for Maintenance Management

1. It Supports Better Maintenance Planning

Accurate asset data allows teams to plan maintenance based on asset needs instead of generic schedules. Preventive maintenance can be adjusted based on condition, usage, and risk rather than applied evenly across all equipment.

Without good data, maintenance plans are often too aggressive for some assets and not aggressive enough for others.

2. It Improves Day-to-Day Execution

When technicians open a work order, asset data gives them context:

- Where the asset is

- What’s failed before

- What parts or procedures are typically involved

This reduces guesswork, repeat visits, and incomplete work.

3. It Reduces Reliance on Memory

In many organizations, maintenance still depends on experienced staff remembering how equipment behaves or how it was fixed last time. That works—until people are unavailable, retire, or move on.

Documented asset data turns individual experience into shared knowledge the whole team can use.

4. It Makes Performance Visible

Reliable asset data makes it possible to answer questions like:

- Which assets fail most often?

- Where is downtime increasing?

- Which assets cost the most to maintain?

Without clean data, these questions lead to opinions instead of answers.

5. It Strengthens the Case for Funding

Maintenance history and condition data, such as deficiencies, are often the clearest signals that an asset needs attention beyond routine repairs. When maintenance teams can show repeated failures, rising costs, or declining condition, capital requests become easier to justify.

Asset data turns maintenance observations into defensible recommendations.

6. It Enables Organizations to Use AI

AI for facilities management only works when the underlying asset data is accurate and consistent. When asset records are complete and connected to work orders, condition details, and history, teams can use AI to make smarter maintenance decisions.

Without good data, AI outputs are unreliable and often reinforce bad assumptions instead of improving performance.

What Happens When Asset Data Is Poor?

When asset data is incomplete or inconsistent:

- Preventive maintenance doesn’t match actual asset needs

- Assets are duplicated or missing in the system

- Maintenance history can’t be trusted

- Reports are questioned or ignored

Over time, teams stop relying on the system and fall back on spreadsheets, emails, or memory, making the problem worse. Learn more about the true cost of inaccurate asset data here.

Asset Data Is Ongoing Work, Not a One-Time Cleanup

Improving asset data isn’t just about importing records or fixing fields once. It requires:

- Standard asset definitions

- Clear naming and classification rules

- Required fields and validation

- Consistent work order processes

Strong maintenance systems help enforce these practices, but ownership and discipline matter just as much.

Get actionable steps to cleanup your asset data in the guide: The Ultimate Facilities Playbook.

Final Thoughts

Asset data may not feel strategic, but it shapes every maintenance decision. It determines how work is planned, how problems are diagnosed, and how performance is measured.

When asset data is treated as a shared source of truth, not just a system requirement, maintenance teams spend less time reacting and more time improving how assets are cared for.

Unlock step-by-step guidance from Nuvolo experts on how to tackle your asset data challenges.

Get the InsightsUnlock step-by-step guidance from Nuvolo experts on how to tackle your asset data challenges.

Get the Insights