What is Smart Maintenance?

Smart maintenance is a data-driven approach to equipment management that uses sensors, software, and analytics to optimize service schedules and predict issues before they occur. It shifts maintenance from reactive and rigid time-based routines to proactive and cost-effective operations. Instead of waiting for breakdowns, teams monitor asset health to look for early warning signals, and prioritize work based on risk and impact.

In this blog, we’ll provide a clear roadmap to transform your operations from a reactive cost center into a proactive, data-driven strategic partner to the business.

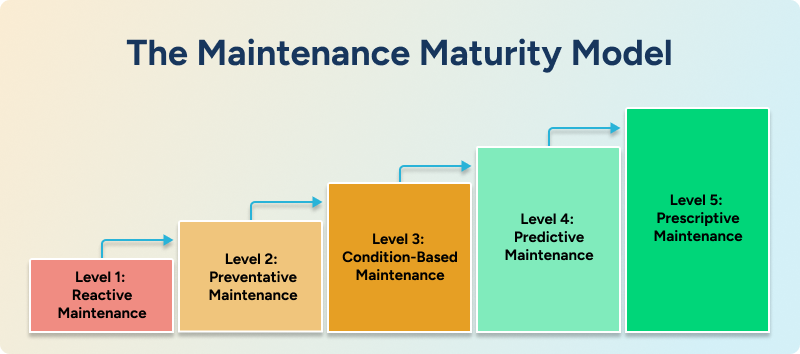

The Maintenance Maturity Model

Understanding where you are today is the first step to planning where you want to go. Here are the five levels of maintenance maturity:

- Level 1: Reactive Maintenance

- Repairs are performed only after equipment fails.

- Level 2: Preventative Maintenance

- Time- or usage-based schedules designed to reduce the likelihood of breakdowns, often the first step toward smarter practices.

- Level 3: Condition-Based Maintenance

- Work is triggered when specific asset indicators cross thresholds (e.g., a refrigeration unit exceeding its temperature limit).

- Level 4: Predictive Maintenance

- Uses condition monitoring and data analysis, often from IoT sensors, to forecast failures and schedule just-in-time interventions.

- Level 5: Prescriptive Maintenance

- Goes beyond prediction to recommend or automate the optimal corrective action using AI, machine learning, and advanced analytics.

Escaping Level 1: The High Cost of Reactive Maintenance

Most teams start at Level 1, and the costs are staggering. The U.S. Department of Energy states that a purely reactive strategy can be 3 to 4 times more expensive than a proactive one. These repair costs compound into shorter asset lifespans, inefficient energy use, compliance risks, and frustrated occupants.

Breaking this cycle starts by moving to Level 2: Preventative Maintenance.

Entering Level 2: Preventative Maintenance

Our recent guide provides strategies that empower facilities teams to take the first step toward a proactive maintenance approach, including:

- Implementing preventative maintenance scheduling

- Effective capital planning based on asset conditions

- Integrating data management platforms and utilizing analytics

The Ultimate Payoff: Linking Smart Data to Smart Capital Planning

As you climb the maintenance maturity ladder from Level 2 onwards, you unlock the ultimate strategic advantage: data-driven capital planning. Every work order, condition reading, and failure pattern captured tells a story. This data provides facilities leaders with undeniable evidence to answer critical questions including:

- Which assets are becoming a drain on our OpEx budget?

- What is the true remaining useful life of our critical equipment?

- Where should we strategically invest our CapEx dollars for the biggest impact on reliability?

This transforms capital planning from an annual guessing game into a precise, proactive strategy. Instead of reacting to a catastrophic failure, you can build a business case to replace an asset before it fails, saving enormous sums on emergency spending and downtime.

Beyond this, it can also provide insights into when organizations are overspending to keep their assets running. For example, when a Nuvolo customer saw that their preventative maintenance repair costs exceeded replacement value, it was a signal for them to shift from maintenance to renewal. They were servicing sump pumps on a fixed schedule, but after tracking the total cost of ownership (TCO), including labor, time, and parts, they discovered their preventative maintenance program was more expensive than replacing the pumps upon failure.

The Bottom Line

Moving up the maintenance maturity ladder is the core mission of modern facilities management. Each step forward, from reactive to preventative to predictive, reduces costs, minimizes risk, and increases the strategic value of your team. Maintenance provides the data and foresight while capital planning provides the funding and timing to act on it.

Together they create the foundation for a connected, intelligent maintenance strategy that not only prevents failures, but optimizes every investment.

Explore how our Asset & Maintenance product can help you cut costs, reduce downtime, and simplify your asset management operations.

Get StartedExplore how our Asset & Maintenance product can help you cut costs, reduce downtime, and simplify your asset management operations.

Get Started